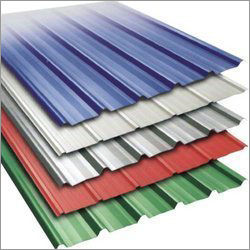

Colored Polycarbonate Sheet

Product Details:

- Type Colored Polycarbonate Sheet

- Size 1.22 x 11.8 m

- Shape Rectangular

- Pattern Plain

- Thickness 1 Millimeter (mm)

- Length 2440 Millimeter (mm)

- Width 900 Millimeter (mm)

- Click to View more

Colored Polycarbonate Sheet Price And Quantity

- 850 INR

- 500 Kilograms

Colored Polycarbonate Sheet Product Specifications

- 1.22 x 11.8 m

- 1 Millimeter (mm)

- 2440 Millimeter (mm)

- Colored Polycarbonate Sheet

- 900 Millimeter (mm)

- Plain

- Rectangular

Colored Polycarbonate Sheet Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 1000 Kilograms Per Month

- 1 Week

- Yes

- Free samples are available

- Carton Box and Plastic Packing.

- All India

Product Description

Flat panels made of polycarbonate that have been stained or dyed with a particular colour are known as coloured polycarbonate sheets. Thermoplastic polycarbonate is a tough and light material prized for its adaptability, transparency, and resistance to impacts.

In relation to coloured polycarbonate sheets, keep in mind the following:

2. Polycarbonate coloured sheets come in a variety of colours to accommodate different design and application requirements. Shades of blue, green, red, yellow, grey, and bronze are typical colours. Custom colour variations may also be available from some manufacturers.

3. Transparency: Polycarbonate sheets - including coloured varieties - are renowned for having a high degree of transparency. They continue to have high light transmission qualities even when colour is applied, allowing light to pass through while diffusing the colour. The colour and thickness of the sheet might affect how transparent it is.

4. Impact resistance: Coloured polycarbonate sheets maintain their conventional polycarbonate sheets' superior impact resistance. Due of their extreme toughness, they can endure collisions without cracking or breaking. This qualifies them for uses including signage, exhibitions, safety barriers, and architectural features where both colour and strength are crucial.

5. UV protection: Some coloured polycarbonate sheets have additional UV protection built into their construction. The UV-resistant coatings or additives help keep the polycarbonate material from deteriorating over time and preserve the colour stability even when exposed to sunshine.

6. Applications: Coloured polycarbonate sheets are used in many different fields and sectors. They are frequently employed in architecture, interior design, advertising, retail, lighting, automobile, and other fields. Availability and specific colour choices may change based on the manufacturer.

7. Similar techniques to those used for ordinary polycarbonate sheets can be used to create and install coloured polycarbonate sheets. To get the correct shape and size, they can be cut, drilled, bent, and thermoformed. Working with coloured polycarbonate sheets requires using the right equipment and techniques, according to manufacturer instructions, and using the right instruments.

It's crucial to evaluate the unique needs, such as impact resistance, light transmission, UV protection, and colour stability, before choosing coloured polycarbonate sheets for a given application. Additionally, it's a good idea to speak with producers or suppliers to make sure the coloured polycarbonate sheet you choose matches your needs.

Call Me Free

Call Me Free