Roof Metal Sheet

Product Details:

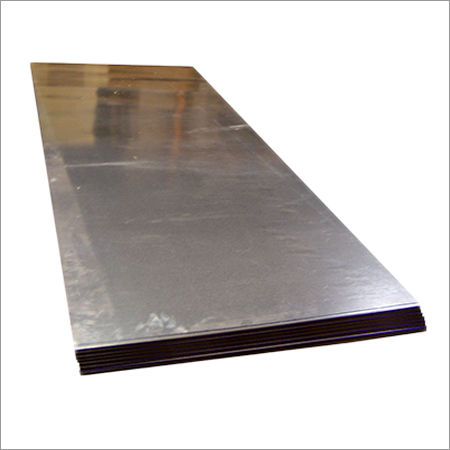

- Material Zinc Alloy

- Type Roof Metal Sheet

- Size 3.5 X 10 Feet

- Shape Rectangular

- Pattern Plain

- Thickness 1 Millimeter (mm)

- Length 6 to 16 Foot (ft)

- Click to View more

Roof Metal Sheet Price And Quantity

- 850 INR

- 500 Kilograms

Roof Metal Sheet Product Specifications

- 1 Millimeter (mm)

- Plain

- 6 to 16 Foot (ft)

- Zinc Alloy

- 1000 Millimeter (mm)

- 3.5 X 10 Feet

- Roof Metal Sheet

- Rectangular

Roof Metal Sheet Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 1000 Kilograms Per Month

- 1 Week

- Yes

- Free samples are available

- Carton Box and Plastic Packing.

- All India

Product Description

Metal roofing sheets and panels, commonly referred to as roof metal sheets or metal roof panels, are strong, weatherproof materials used to cover roofs. These sheets often come in a range of shapes and finishes and are constructed from various metals including steel, aluminium, or zinc.

Here are some essential details concerning metal sheets for roofs:

1. Roof metal sheets are typically constructed from metals like steel, aluminium, or zinc. The particular kind of metal used will rely on a number of elements, including price, endurance, and desired aesthetics.

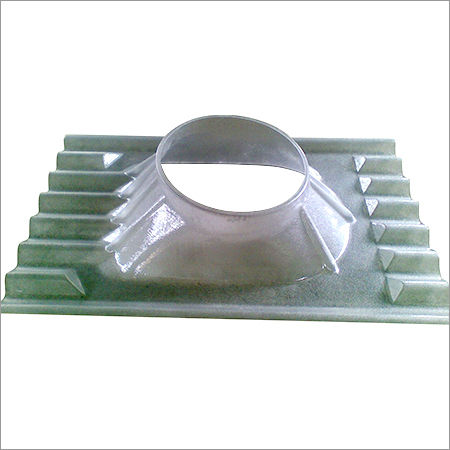

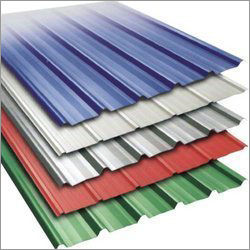

2. Roof metal sheets are available in a variety of profiles or shapes, which have an impact on the roof's appearance and functionality. Corrugated, standing seam, and ribbed profiles are examples of typical profiles. Regarding strength, water shedding capacity, and design aesthetics, every profile has its own distinct qualities.

3. Durability: Metal roofing sheets are renowned for their sturdiness and lifespan. Extreme weather conditions including severe winds, persistent rain, snow, and hail are not a problem for them. Metal sheets are a dependable option for long-term roof protection since they are resistant to damage from fire, rot, and insects.

4. Roof metal sheets have outstanding weather resistance characteristics. They are made to efficiently shed snow, water, and other debris from the roof surface, reducing the possibility of leaks and other problems. Additionally resistant to UV rays, metal sheets lessen the possibility of fading or deterioration over time.

5. Lightweight: Metal sheets are relatively lightweight when compared to other roofing materials like concrete or clay tiles. Because of this quality, they are less difficult to handle during installation and the overall structural load on the building is decreased.

6. Energy efficiency: Metal roofing sheets can be created with energy-saving features. To lessen heat absorption and increase energy efficiency in the structure, they may feature reflecting coatings or insulation layers. In warmer climes, this can assist in reducing cooling expenses.

7. Options for personalization and aesthetic improvement: Roof metal sheets are offered in a variety of hues, textures, and coatings. The metal sheets can be coated in many ways, such as paint or protective layers, to get the required finish, corrosion resistance, and durability.

8. Installation: To form a watertight seal, roof metal sheets are normally erected by overlaid or interlocked panels. Depending on the profile and the manufacturer's instructions, the precise installation technique may change. To maintain a safe and reliable roof system, it is crucial to adhere to suitable installation procedures.

For residential, commercial, and industrial buildings, metal roofing sheets provide a flexible and dependable roofing solution. It's crucial to take into account aspects like the climate, building design, budget, and desired aesthetics when selecting roof metal sheets. For advice on the best metal sheet specification for your particular roofing needs, speak with manufacturers or roofing experts.

Features:

- Immaculate finish

- Durable

- Cost effective

- Offered in various shapes and thickness.

Specification

|

Features |

Water Proof |

|

Technique |

Cold Rolled |

|

Surface Treatment |

Coated |

|

Material |

Fiberglass |

|

Thickness |

4mm |

Call Me Free

Call Me Free